Flexographic Printing

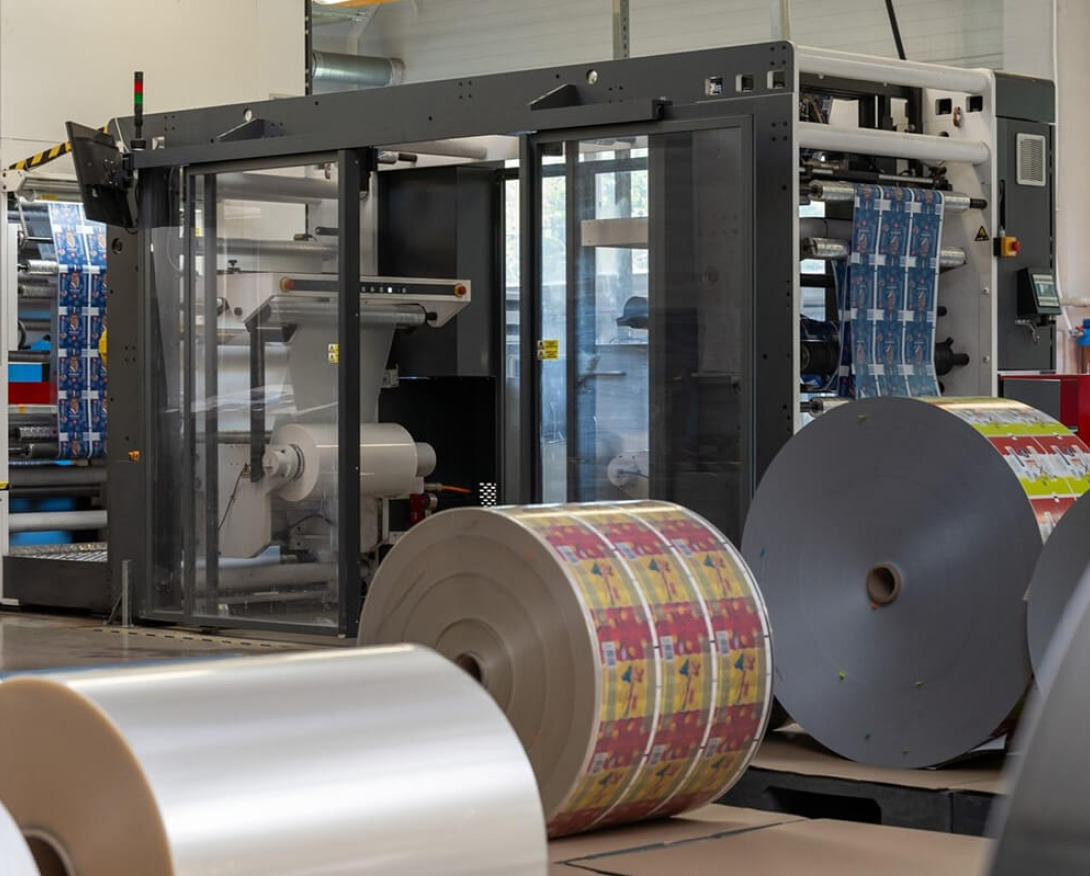

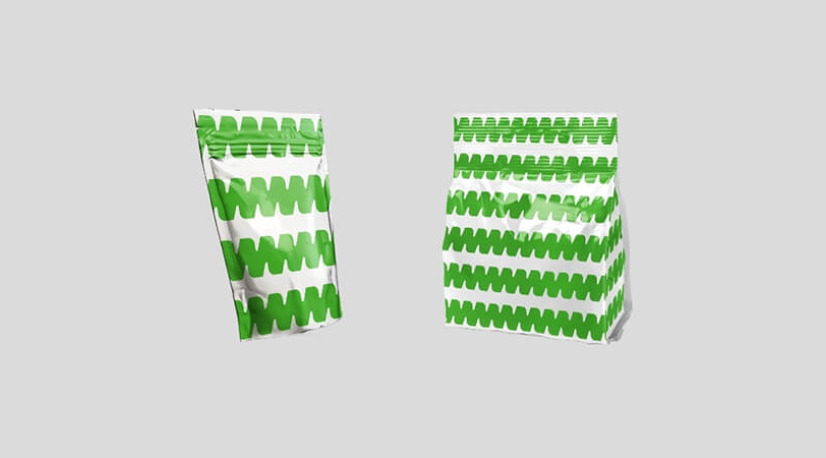

Constantly evolving flexography opens the door to the high-quality flexible packaging market. This technology is widely used across confectionery, dairy, ice cream, dry goods, frozen products, and various other industries, enabling printing on a broad range of materials. Post-printing processes such as partial or full varnishing and other effects not only provide protection but also add a distinctive edge to your products!

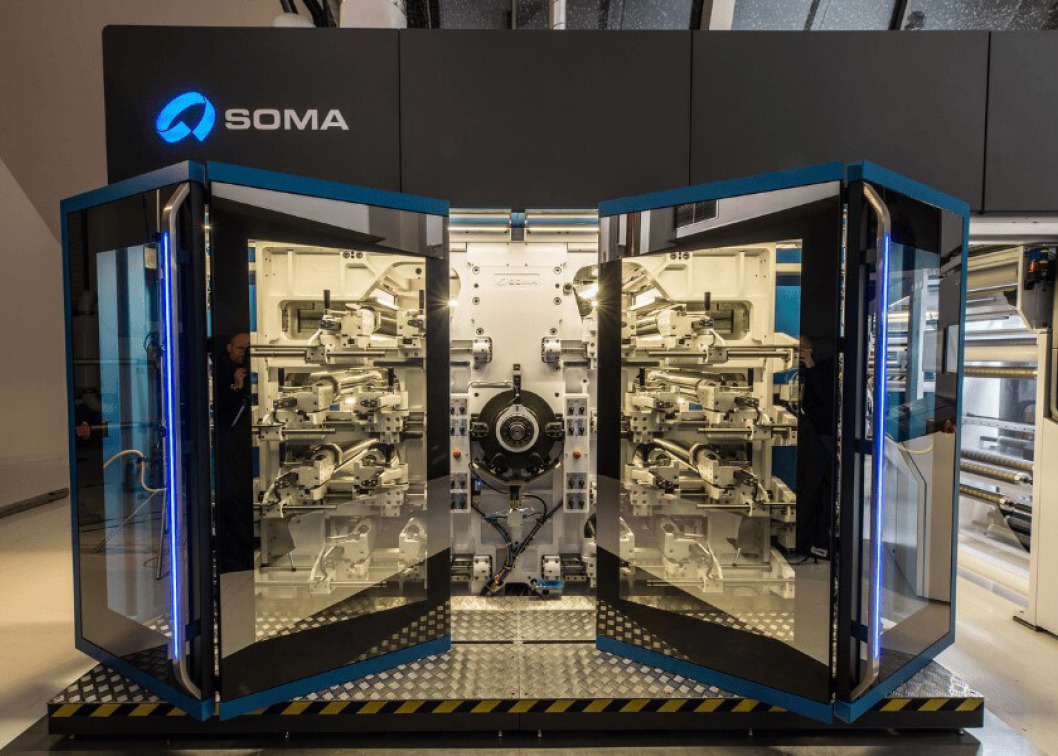

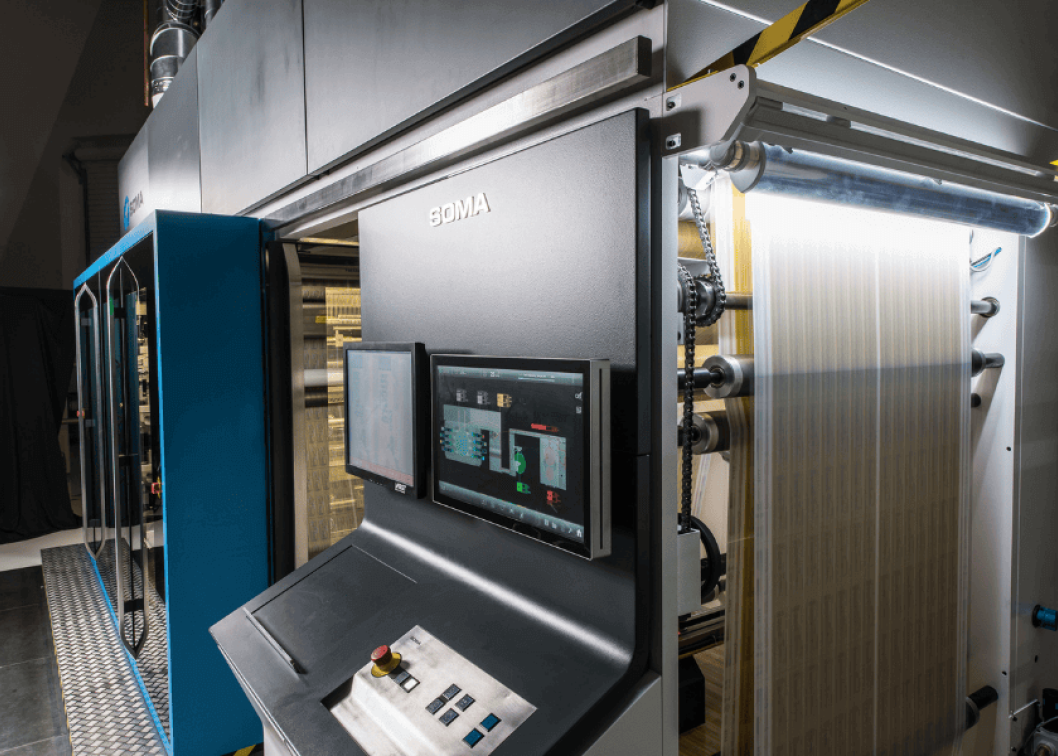

- Quality, precision, and outstanding colour definition High-resolution 8-colour roll-fed printing ensures smooth colour transitions and exceptional quality even for the finest details. We tailor each design individually, carefully matching CMYK and Pantone colours. With the help of X-Rite’s quality control equipment and a spectrodensitometer, we prepare inks quickly and precisely—even when printing across different surfaces.

- Cost-effective process The flexographic process eliminates unnecessary production costs. Reusable photopolymer plates make it an excellent choice for medium to large-volume production runs.

- Fast and efficient production cycle Flexography offers high productivity and swift job changes. The printing operates at maximum speed while maintaining print consistency. Printing, laminating, and die-cutting stages follow one another seamlessly, maintaining optimal production intervals. This allows for rapid delivery of high-quality, customised packaging solutions.

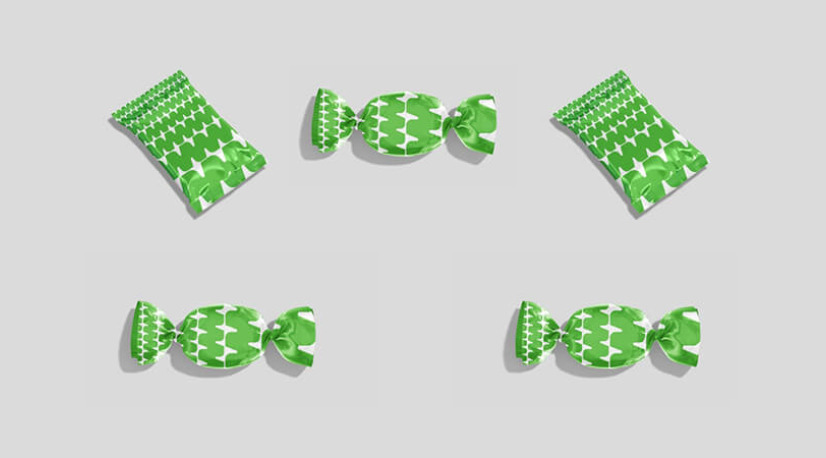

- Material versatility Effortless printing on materials with diverse surfaces, thicknesses, and properties. Both single-layer and multi-layer structures are used, created through the lamination of various substrates. Thanks to the wide range of materials, the packaging can offer features such as twist retention, dead-fold and barrier properties, as well as additional functionalities: anti-fog, easy-peel, and re-close options.

Flow pack, wrap, and twist wrap packaging, along with thermoforming and lidding films, are engineered to meet specific industry requirements and ensure exceptional performance.

A versatile range of bags suitable for both manual and automated packaging: stand-up pouches (Doypacks), three-seam vacuum bags, side-fold bags, and bottom-fold bags.

Discover tailored solutions for your products and turn your success story into print.